Beta hydroxyalkylamide (HAA), a commercial alternative crosslinker to TGIC, that reacts with the same or improved versions of acid functional polyester resin used with TGIC. However, do you know the types of HAA crosslinkers used for powder coatings?

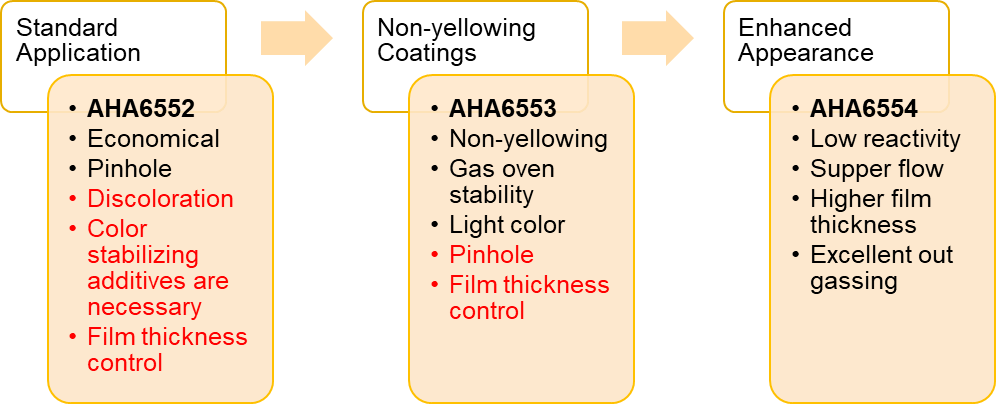

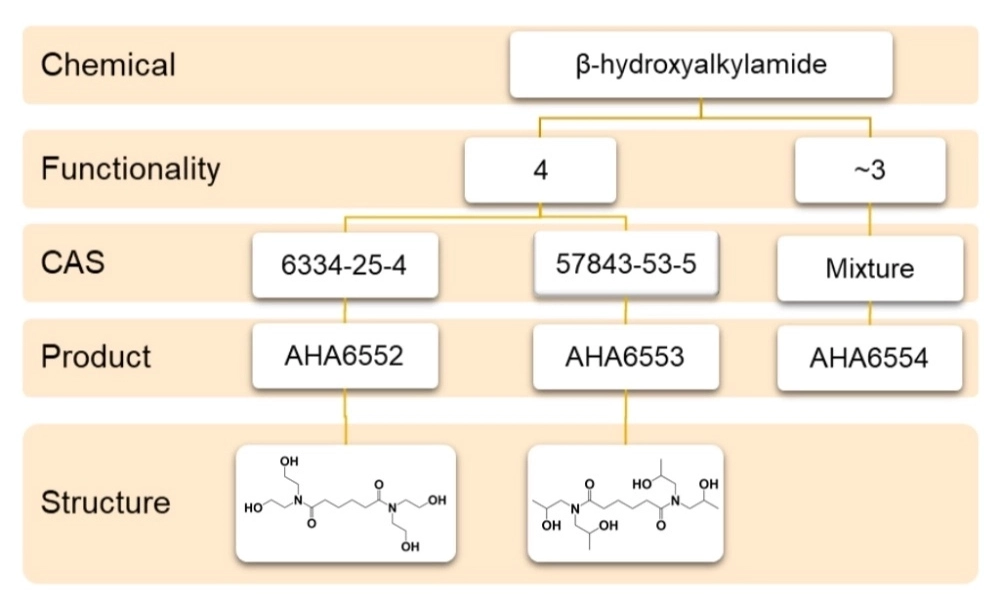

There are three commercial HAA crosslinkers with different structures provided by AHA.

What’s the different of those HAA crosslinkers when powder coatings formula with?

The performance of crosslinkers, TGIC and HAAs, has compared from different aspects with the formula as below:

| Components | Part by weight | Remark | |

| CRYLCOAT 2630-2 | 603(606) | ||

| CRYLCOAT 2441-2 | 593.3 | ||

| HAAs | 35(32) | ||

| AHA6810 | 44.7 | TGIC | |

| R-960 | 200 | 200 | |

| Flow Modifier | 10 | 10 | |

| Barium sulfate | 150 | 150 | |

| AHA 4100 | 2 | 2 | Benzoin |

| Total | 1000 | 1000 | |

| Cure Cycle | 200℃/10min | ||

| Overbake | 200℃/60min and 230℃/30min | ||

Reactivity

| Crosslinker | AHA6810 | AHA6552 | AHA6553 | AHA6554 | |

| PCI | 6 | 6 | 6 | 6 | |

| Film thickness | 60-70 | 65-75 | 70-80 | 75-85 | μm |

| Gloss | 95.6 | 96.5 | 95.9 | 96.0 | 60° |

| Impact | 50Kg*cm | 50Kg*cm | 50Kg*cm | 50Kg*cm | D/R |

| Gel time | 239s | 98s | 115s | 139s | 200℃ |

There are some differences in the reactivity of the four crosslinkers above. The functionality of AHA6554 is about 3, which is less than AHA6552 and AHA6553, so the reactivity of AHA6554 is reduced, which is conducive to obtaining a pinhole free HAA based powder coating.

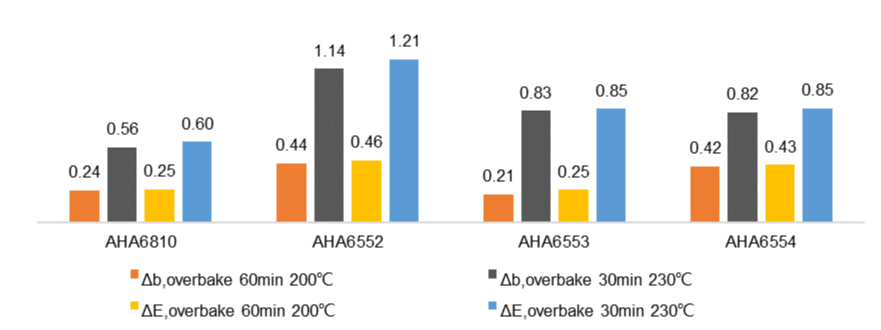

Overbaking resistance

Yellowing under overbaking condition has been done with two different conditions, 200℃/60min and 230℃/30min, color difference as below:

Undisputed, AHA6810(TGIC) offers the best overbaking resintance and AHA6552(standard HAA) shows the most obvious color difference. Of the three HAA crosslinkers tested, AHA6553 and AHA6554 was closest to the TGIC’s color difference.

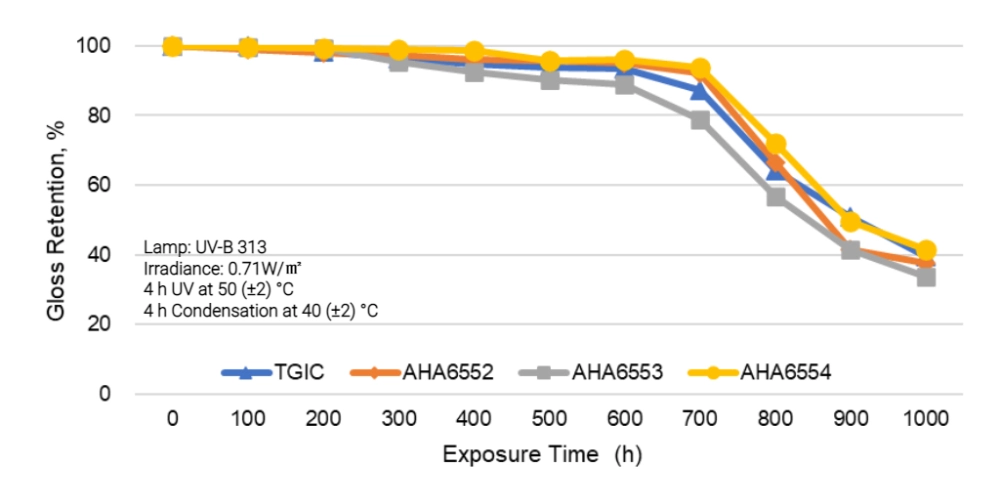

Durability

Three different HAA crosslinkers delivered a durable, UV-resistant finish similar to TGIC powder coatings when formula with same resin.

(Albester 6140, a super durable carboxyl terminated polyester resin from Synthemer).

Conclusion